304 stainless steel belongs to the austenitic stainless steel, is one of the most common varieties of stainless steel.

In different national standards written in different ways.

304 is the United States AISI and UNS write astm 304 stainless steel

Chinese GB06Cr18Ni9

Japanese JIS SUS304

British BS304S15

EU ES 1.4301

Korea KS STS304

Indian IS 07Cr18Ni9

For other applications of 304 stainless steel in kitchenware, you can read another article on our website “304 stainless steel”

ss 304 chemical composition

As you can see from the Chinese and Indian grades, 304 stainless steel has the nickel content of about 9%(It’s actually 8-10%) and the chromium content of 18% or more, for other properties, please see the following table.

304 STAINLESS STEEL COMPOSITION

| Fe | Cr | Ni | Mn | Si | C | P | S |

| Other | 18-20 | 8-10 | ≤2 | ≤1.0 | ≤0.08 | ≤0.045 | ≤0.03 |

1, Iron: is the basic metal element of 304 stainless steel;

2, Chromium: in 304 stainless steel, chromium is the main alloying element, chromium combined with oxygen can generate corrosion-resistant Cr2O3 passivation film, is one of the basic elements of stainless steel to maintain corrosion resistance, chromium content increases can improve the passivation film repair ability of steel, general stainless steel chromium content must be more than 12%; chromium can significantly improve the 304 stainless steel tensile strength, hardness and wear resistance, but at the same time reduce plasticity and toughness. Chromium can also improve the oxidation resistance and corrosion resistance of 304 stainless steel.

3, Nickel: is the main austenite forming element, can slow down the corrosion phenomenon of steel and grain growth during heating; nickel can improve the 304 stainless steel tensile strength, while maintaining good plasticity and toughness. Nickel has a high corrosion resistance to acids and bases.

4, Manganese: in the steelmaking process, manganese is a good deoxidizer and desulfurizer, manganese amount increases, weakening the corrosion resistance of 304 stainless steel, reducing the welding performance.

5,Silicon: silicon can significantly improve the elastic limit of steel, 304 stainless steel 304 stainless steel yield strength and 304 stainless steel tensile strength. Silicon and chromium combination, have improved corrosion resistance and antioxidant effect. It should be noted that the amount of silicon increases, will reduce the welding properties of steel. Usually less than 1%.

6, Carbon: is a strong austenite forming element, can significantly improve 304 stainless steel yield strength, but the higher the carbon content in carbon steel, the worse the plasticity, in addition, carbon also has a negative impact on corrosion resistance. 304 stainless steel in the carbon content increases, 304 stainless steel yield strength and 304 stainless steel tensile strength increases, but plasticity and impact decreases, high carbon content will also reduce the corrosion resistance of 304 stainless steel.

7, Phosphorus: in general, phosphorus is a harmful element in 304 stainless steel pipe, so that the welding performance is bad, reduce plasticity, so that the cold bending performance is bad.

8, Sulfur: sulfur in general is also a harmful element. Reduce the ductility and toughness of 304 stainless steel pipe, sulfur is also detrimental to the welding properties, reducing corrosion resistance.

304 stainless steel material properties

Because 304 stainless steel is widely used, in different uses, it requires different properties.

The market common 304 stainless steel coil properties are usually:

| TENSILE TEST | Hardness | ||

| Tensile Strength(MPa) | Yield Strength(MPa) | Elongation(%) | HV |

| 700 | 280 | 53 | 170 |

However, in practical applications, there are often higher requirements for a particular aspect of 304 stainless steel performance.

According to the different use requirements, 304 stainless steel has been targeted to improve, the following are some of the very close materials changed from 304.

304L-L means Low, referring to the low carbon content of 304 stainless steel, the carbon content required less than 0.03% to improve the welding properties.

304N-N means Nitrogen, refers to the addition of nitrogen in 304 stainless steel, the content is 0.10 ~ 0.16%, improve the cold forming properties of 304 stainless steel.

304D-Like 201 stainless steel is a nickel-saving material, reducing the nickel content of stainless steel to 2.8%, reducing the corrosion resistance of the material, the tensile properties remain the same or even better, not suitable for making kitchenware, mainly in industrial applications.

304J1-add copper element to 304 material, while reducing the nickel content, also belongs to a kind of nickel-saving materials, improve the tensile properties of 304, other aspects slightly worse than 304.

304DQ – without changing the composition of 304, by changing the annealing process, thus improving the tensile properties of 304 stainless steel, is the most suitable for making kitchenware type, deep drawing products.

|

TENSILE TEST |

Hardness |

||

| Tensile Strength(MPa) | Yield Strength(MPa) |

Elongation(%) |

HV |

|

700 |

280 |

63 | 170 |

Comparison of different materials and 304 stainless steel

303 vs 304 stainless steel

303 stainless steel is austenitic easy to cut, wear-resistant, acid-resistant stainless steel, in order to improve the performance of the steel, can be added to the steel not more than 0.6% of molybdenum, can be resistant to ablation.

303 stainless steel mechanical properties after annealing stress relief, tensile 515MPa, 303 stainless steel yield strength 205MPa, elongation 40%. The standard hardness of stainless steel 303 HRB 90-100

The elongation of 304 stainless steel is significantly higher than that of 303 stainless steel, which is more suitable for making tensile products such as kitchenware with larger deformation.

Stainless steel 304 VS 316

1, chemical composition is different: 304 does not add molybdenum elements, while 316 has added molybdenum elements.

2, corrosion resistance is different: 304 contains only 9% nickel elements, while 316 contains 12% nickel elements, so 316 corrosion resistance and other aspects of better.

3, different performance: 304 corrosion resistance, acid resistance, alkali resistance and other aspects of better, and 316 because of the addition of molybdenum elements, so better resistance to chloride corrosion, heat resistance.

430 vs 304 stainless steel

- Corrosion resistance performance: 430 stainless steel contains chromium elements 16-18%, basically no nickel elements, 304 stainless steel contains more chromium-nickel elements, so 430 stainless steel corrosion resistance is not as good as 304 stainless steel.

- Stability performance: 430 stainless steel is a ferrite form of stainless steel, 304 stainless steel is austenitic form, 304 stainless steel is more stable than 430 stainless steel.

- Thermal conductivity: ferritic 430 stainless steel thermal conductivity than austenitic 304 stainless steel thermal conductivity is better

- Mechanical properties: 430 stainless steel added a stable chemical element titanium, the mechanical properties of the welded parts than 304 stainless steel.

- Whether magnetic: 430 stainless steel is ferritic, magnetic, 304 stainless steel is austenitic stainless steel, no magnetic, which is the simplest way to distinguish between the two, of course, 304 stainless steel in the stretching and deformation of larger later because of internal molecular structure changes produce weak magnetic, so this detection method is not completely reliable.

stainless steel, 201 vs 304 food grade

- Different composition, 201 stainless steel in the manganese content is high, and acidic substances in contact with the manganese will be easily precipitated. For 304 stainless steel, the composition of the nickel element is very important, directly determines the corrosion resistance of 304 stainless steel and its value.

- Different performance, 201 stainless steel is more brittle and hard than 304 stainless steel, because the carbon content of 201 stainless steel is higher than 304 stainless steel.

- 304 stainless steel has better corrosion resistance, acid and alkali resistance, etc.

- 201 is a nickel saving material, with the widespread use of 201 stainless steel in China and Southeast Asia, some more adaptable 201 materials have come into being, I will write an article later for the types of 201 stainless steel in China, performance, and use process.

Application of 304 stainless steel material

304 stainless steel is a general-purpose stainless steel, good overall performance makes it a lot of applications in many fields, include 304 stainless steel food grade.Best food grade stainless steel

1, 304 stainless steel can be used for food production equipment, with the improvement of quality of life, the tableware we use must be manufactured using 304 stainless steel food grade, 304 stainless steel is exactly the right material for processing these tableware.

2, can also be used for auto parts, now more and more cars, windshield wipers, mufflers, mold products on the car are available 304 stainless steel for production.

3, applicable to medical equipment, in hospitals we can see the placement of drugs such as tool cabinets are available 304 stainless steel material for production.

4, industrial building roofs and sidewalls. The use of 304 stainless steel in a dry indoor environment works quite well.

5, 304 stainless steel is not only suitable for the above industries, but also widely used in chemical, agricultural, marine components, etc.

304 stainless steel main shape

Among the various applications, the largest number of applications in coils. 304 stainless steel plate and discs are obtained on the basis of coils, 304 stainless steel strip processing, all belong to the category of coils. In addition to coils, there are also stainless steel bars, stainless steel tubes, and stainless steel castings customized to the customer.

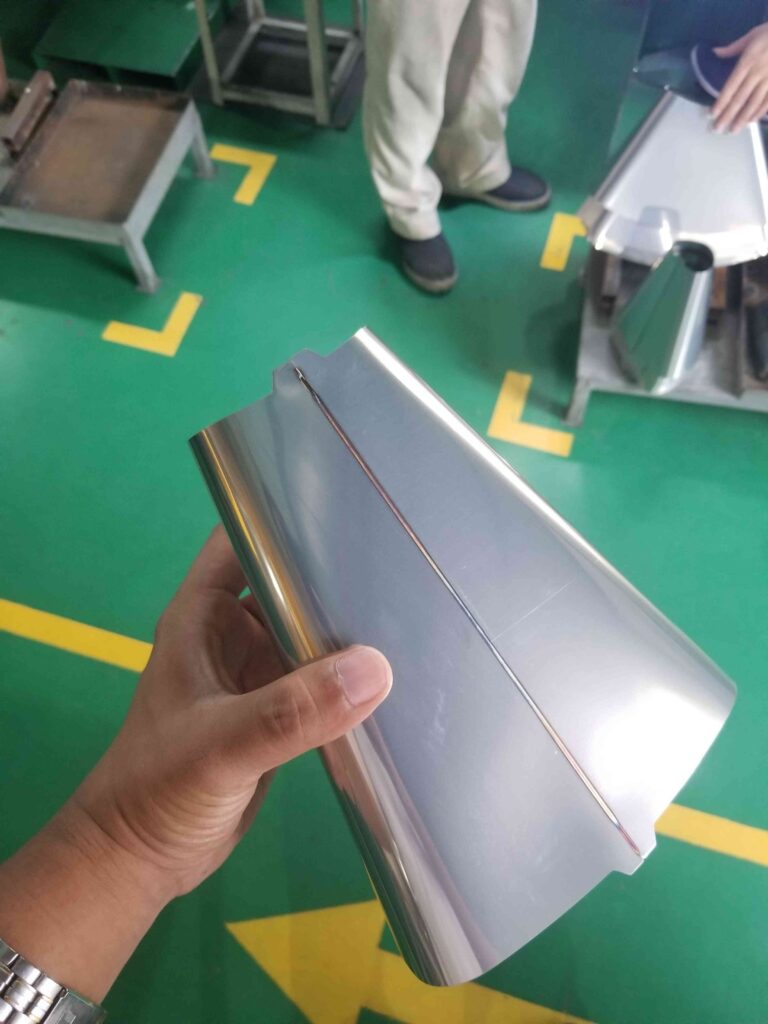

304 stainless steel surface

304 stainless steel surface processing makes it better in various fields of application.

1.Stainless steel surface finish grade 11 Ra 0.1 ~0.2μm 8k mirror stainless steel, good surface effect (fine polished stainless steel)

- Stainless steel surface finish grade 10 Ra 0.2 ~0.3μm 6k mirror stainless steel, slightly stronger than the BA surface, some positions hairline visible

- stainless steel surface finish grade 9 Ra 0.4 μm 4k close to the BA surface, ordinary polishing or direct rolling effect.

- Hairline surface: mainly the difference between long and short filaments, matte surface, no feel.

- color plating: there are many kinds of color plating process, according to the use of different processes, the color is mainly a variety of gold copper, black, beige, etc.

304 stainless steel precautions

1.304 stainless steel is a good overall performance, but not a panacea, the element of chlorine has a great corrosive effect on it, so in use if a large number of long-term exposure to the element of chlorine, it is best to use better 316 stainless steel materials.

Chlorine ions are widely present, such as salt / sweat / seawater / sea breeze / soil, etc.. Stainless steel in the presence of chlorine ions in the environment, corrosion is rapid, even more than ordinary mild steel

In the kitchen, soy sauce and salt are very corrosive to stainless steel, so try not to use 304 stainless steel for long-term storage of soy sauce and salt.

- 304 stainless steel has good tensile properties, but for kitchenware and other deep drawing products, it is best to choose better tensile properties of 304DQ or 316 stainless steel to produce to ensure that the finished product can be smoothly stretched.

- 304 stainless steel itself is not magnetic, but after processing deformation, will produce micro-magnetic, so the magnetic is not an accurate way to judge 304 stainless steel.

- Austenitic stainless steel in the tensile deformation is large, because the internal stress is too large, occasionally after the processing of their own cracking, this time in 5 minutes to 10 days can happen. The method of prevention I will be introduced in the later blog.

The above is the introduction of 304 stainless steel material, there is not a comprehensive place please point out, also welcome to leave information, we can communicate more topics.

I am a professional supplier of 304 stainless steel materials, and will introduce 430 410 201 and other stainless steel materials in the future.

Leave A Comment